AcoustiGuard™ Quilted Absorption Panels

Sound Attenuation

The AF series panel is a versatile noise control product that combines durable facings with quilted acoustic absorbers.

The quilted panels can be easily installed on factory wall. Panels can be easily site-cut and the edges rebound to fit around light switches, control panels and other obstructions.

The quilted panels can be easily installed on factory wall. Panels can be easily site-cut and the edges rebound to fit around light switches, control panels and other obstructions.

Unit of Measure

| Items |

/Asset/Quilted-Absorption-Panel.jpg /Asset/Quilted-Absorption-Panel.jpg AF AcoustiGuard™ Quilted Absorption Panels |

/Asset/Quilted-Absorption-Panel.jpg /Asset/Quilted-Absorption-Panel.jpg AF2 AcoustiGuard™ Quilted Absorption Panels |

/Asset/Quilted-Absorption-Panel.jpg /Asset/Quilted-Absorption-Panel.jpg A2F AcoustiGuard™ Quilted Absorption Panels |

/Asset/Quilted-Absorption-Panel.jpg /Asset/Quilted-Absorption-Panel.jpg A2F2 AcoustiGuard™ Quilted Absorption Panels |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Applications |

N/A

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Performance Data |

N/A

|

N/A

|

N/A

|

N/A

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| High Performance Noise Control |

N/A

AcoustiGuard™ AF is an attractive, fire rated absorption panel that can be easily attached to any 'hard surface' or hung as acoustic baffles. These quilted panels are designed to reduce reverberant (reflected) noise and absorb broadcast noise along transmission paths. They are ideal for surfaces in large open areas like factory walls and gymnasiums. Other treatments include noise absorbing liners for operator stations or equipment housings. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

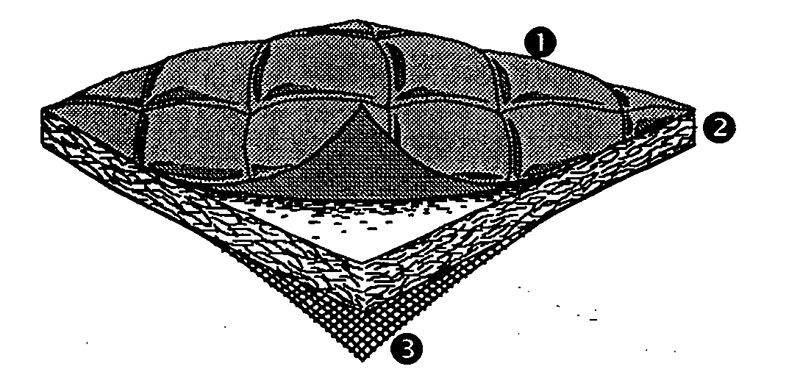

| Panel Configuration | N/A Acoustic glass fiber is quilted in a 'diamond' or 'straight' pattern and faced with a vinyl coated fiberglass cloth resistant to most industrial contaminants. The back of the panel is faced with a fire rated scrim - face goods optional on both surfaces. All panel edges are bound and fitted with grommets and Hook & Loop style fasteners as required. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard Thickness | N/A 1" and 2" nominal with special orders for panels up to 4" thick. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard Width | N/A From 54" rollgoods, 50' long rolls in 1 inch absorber, 25' long rolls in 2 inch absorber. Custom sizes and shapes available. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard Facing |

N/A

Minus 20° to 180°F temperature range. Optional high temperature facing up to 550°F is available. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colors | N/A Silver/grey (standard) and optional beige. Special panels can be made using different facings or films for specific environmental application. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Attractive Surface Finish | N/A Vinyl coated fiberglass cloth is quilted directly to the fiberglass absorber using high strength thread. Available in attractive 'diamond' or 'straight' quilt pattern. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Flammability | N/A Meets Class 1 requirements. Low smoke and flame spread. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

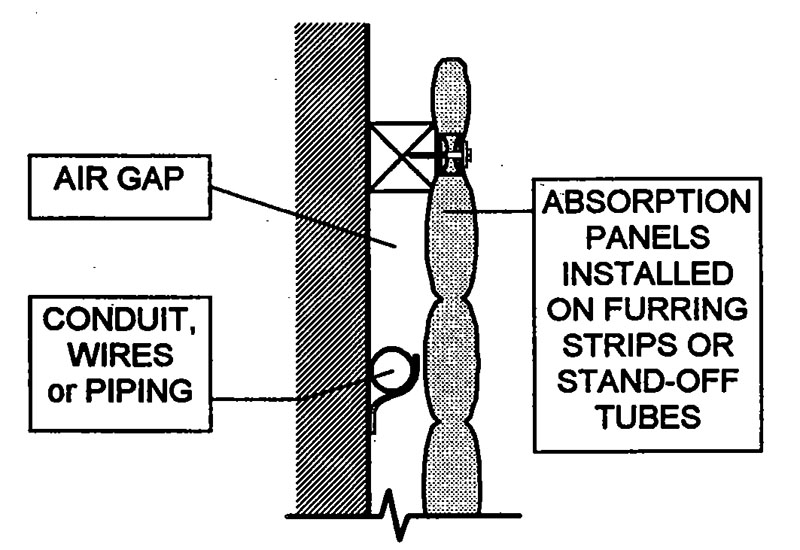

| Installation |

N/A

Installation is fast and easy using standard mechanical fasteners. It is recommended that wall panels be installed on 1" or 2" furring strips or stand off tubes. This will allow panels to clear most piping and conduit. Performance can actually be increased by utilizing this air gap. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Custom Panels |

N/A

CUSTOM PANELS can be manufactured to fit the interiors of equipment housing and cabinets. Quilted absorption panels are contamination resistant and suitable for low or high temperature applications. Custom panels can be fitted with mechanical fasteners or Hook and Loop strips for easy installation and removal. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Common Styles |

N/A

Illustration shows the composite layers of AcoustiGuard™ AF series panels.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material | N/A Fiberglass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Material Thickness | N/A 1" | N/A 1" | N/A 2" | N/A 2" | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||